Once created you can modify the Press/Pull operation by replacing -0.2 mm value with “holgura” (or your preferred term). (“holgura” is the translation of clearance in Spanish, use you own term)

#Autodesk fusion 360 export stl software

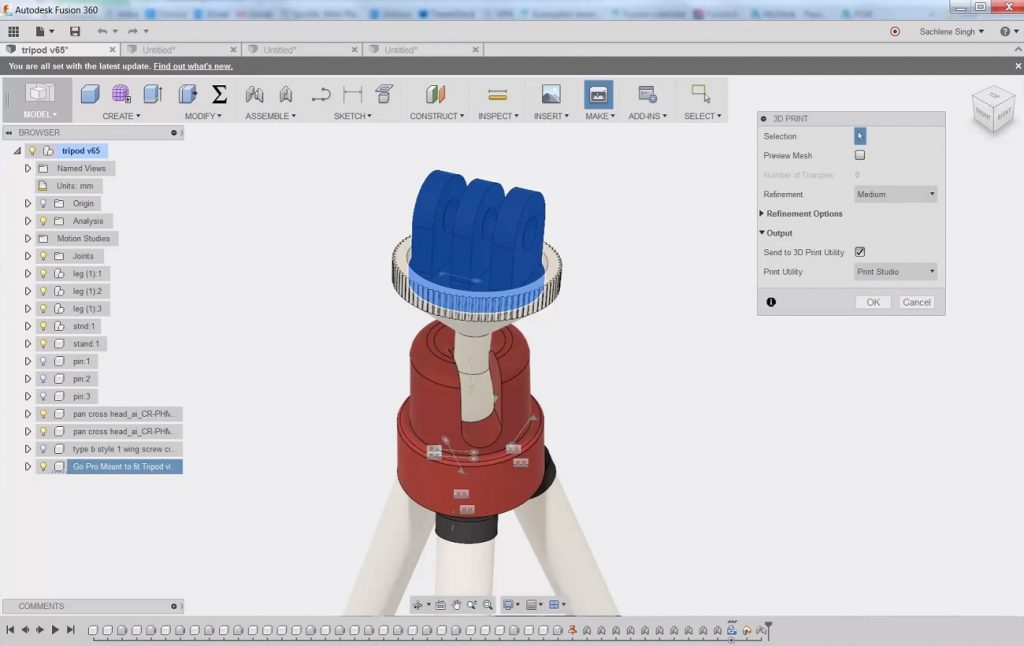

The beauty of working with parametric software such as Fusion 360 is that you can convert this -0.2 mm value in a parameter that you can change any time, and use it in all Press/Pull operations that you have applied, or will apply.įor this we create a parameter “holgura” in Modify – Change Parameters. In a threaded hole, you have to apply the same by selecting all inner faces of the thread. In a hole, simply select the hole inner face and move it out (-0.2 mm in the example, so -0.4 mm in diameter). In Fusion 360 we have the tool Modify – Press/Pull (shortcut key ‘Q’) that allows you to offset one or several faces. In this case your option is to modify the design.

But this affects the whole part and it may happen that you only want to apply this toa hole for example, or a hole in a vertical orientation that would not be affected by expansion that is only horizontal. With the slicer you can use the horizontal expansion parameter to modify the size of the part in the horizontal plane and offset for the material shrinking. Here you have an example of tolerances test. There are several models in Thingiverse that you can print to confirm what you need for a specific material and 3D printing setting. It is usually 0.1 to 0.5 mm in FFF 3D printers.įirst thing is to test the machine to know the tolerances that it has. One of the most relevant is the type of material, and ideally in these cases is to adjust the model with enough clearance in parts where there are inserts or threads. Apply clearance by parameters for 3D printer toleranceĮach 3D printer has its own tolerances in relation to many parameters. Effect of 3D printing fillets and chamfersġ. Check overlap between solids with Interference Apply clearance by parameters for 3D printer tolerance

Set the top offset to 0mm (assuming we will be cutting this from material that is the same thickness as the part) and press OK. Bump the side offset up by to 5mm, to give us a bit of a margin when cutting the part.Click one of the points on the top of the yellow semi-transparent stock box.Select ‘Box Point’ to select a stock point to be the origin for our job.Select the axis we want to use for Z, in the pictured example, the green axis is used.In the Setup tab, select the orientation drop down and click ‘Select Z axis/plane & X axis’.We need to set the coordinate system such that the Z-axis points up, while the x and y-axis from the a plane matching the top of the stock (the yellow semi-transparent box). Most importantly, it lets us setup how our stock will be orientated in our mill. It lets us tell Fusion a few details about the stock, or the material we will be using to cut the part from. A setup holds general properties about the milling job.

0 kommentar(er)

0 kommentar(er)